pelletizing system for feed mill

Pelletizing system is the core process in the feed plant. Because it is the key production of high quality nutritional feeds to meet different animals’ taste. While the feed pellet mill is the main pellet mill equipment. The pelletizing system is composed with forcing soft feed through ring die hole to form feed pellets which are cut into pre-determined size. The feed pellet mill has been developed with different in design. The feed pellets will have the same designed structure and formulation to make sure the stock is feed as intended.

Pelletizing System for Feed Mill

Now the feed pellet mill in design has one or two more conditioning units positioned where water or vegetable oil can be added to improve pelletizing ability and quality. The water is added in the form of steam at times which softens the feed pellets and gelatinizes the starch content of raw material in order to process firm feed pellets. From the conditioner, the feed pellets fall into the pelletizer. In the pelletizer, the rollers push the raw materials through the holes of ring die to form feed pellets. Generally, the ring die rotates itself and on its outer-side stationary knives cut the feed pellets into pre-set length you wanted. Then the feed pellets are transferred into a cooler to remove moisture content and heat which generate during pelletizing process. Through the cooler, the feed pellets are apt to package and store for further purposes.

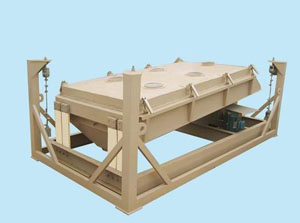

Cooler for Pelletizing System

Other Equipments for Pelletizing System

Pelletizing System for Feed Mill

|

|

| Workshop | Feed Mill Equipment |

|---|

Now the feed pellet mill in design has one or two more conditioning units positioned where water or vegetable oil can be added to improve pelletizing ability and quality. The water is added in the form of steam at times which softens the feed pellets and gelatinizes the starch content of raw material in order to process firm feed pellets. From the conditioner, the feed pellets fall into the pelletizer. In the pelletizer, the rollers push the raw materials through the holes of ring die to form feed pellets. Generally, the ring die rotates itself and on its outer-side stationary knives cut the feed pellets into pre-set length you wanted. Then the feed pellets are transferred into a cooler to remove moisture content and heat which generate during pelletizing process. Through the cooler, the feed pellets are apt to package and store for further purposes.

Cooler for Pelletizing System

Other Equipments for Pelletizing System

|

|

| Grading Rotary Sieve | Triple Roller Crumbler |

|---|

Start your exciting business journey with KMEC Feed Pellets Guide Now!!

Your privacy is safe with us. We hate spam as much as you.

Please take no hesitation to contact us via the information below:

Henan Kingman M&E Complete Plant Co., Ltd

Add: Suite E, 3/F, Jinhao Business Bld., Renmin Rd. Anyang, Henan, P.R.C.

Tel: (86) 0372-5953961

Fax: (86) 0372-5951936

E-mail: info@topfeedmill.com